Initial Situation

In a current automation project of a special-purpose machine manufacturer, the commissioning date was postponed because of delays by the customer. Due to the complexity of the system, however, the processes in the control software could only be tested fully on the real machine – the machine builder would have had to wait for the commissioning date for all remaining tasks.

Solution

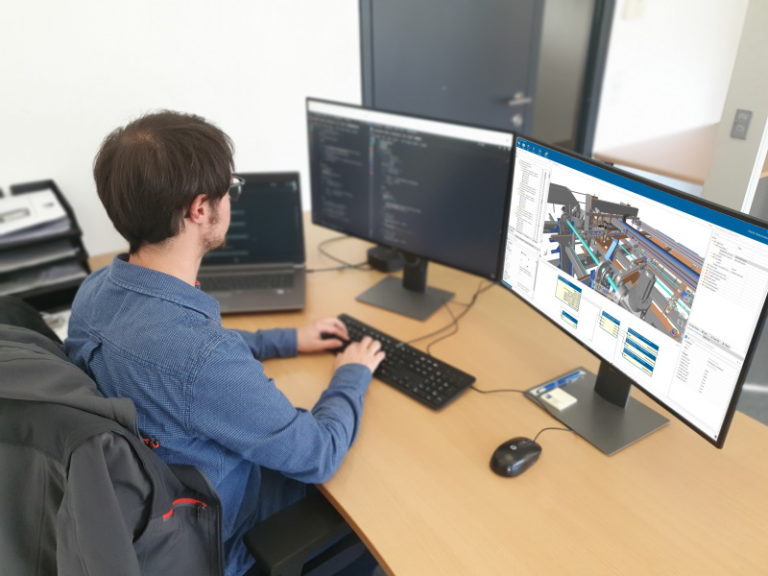

Within an extremely short period of time, Eberle Automatische Systeme was able to provide the machine manufacturer with a functional digital twin of the planned system.

In a joint kick-off meeting, the functions of the machine were developed and necessary files such as CAD data of the machine and EA lists were exchanged. The legal framework was also established. After the digital twin was handed over to the machine manufacturer, their control technicians could immediately start testing and refining the processes.

Axles that could move into each other and had to be interlocked, material handling, system acceleration and idling, manual operation, automatic operation and alarms – all this could be tested on the digital twin and put into virtual operation. The mechanical components of the real machine were not available at that time. The end customer was involved during the entire development of the processes and was able to contribute requests and suggestions.

// Contact

Similar challenges? We are happy to support you with our Jumpstart-Service!

English

English Deutsch

Deutsch