IoT Showcase

An online showcase for modern, networked data visualization and data recording with targeted and fast informationaccess. BEKO and digifai have cooperated to develop a showcase that demonstrates how the combination of both solutions takes data collection and visualization to a new level. This makes processes more traceable and easier to follow. Modern technologies make it possible to integrate solutions into existing systems without a big time and trouble.

An end-to-end solution from digifai

The IoT platform control was initiated and developed by digifai as an universal data platform for industrial use. The goal was always to bring all process data from different data sources and data types into a central platform. Over time, a significant ecosystem has built up to enable Iot platform control via many different data source interfaces. Today, its use is not limited to industrial applications. For example, control is also used for energy monitoring and in building technology. control creates a central collaborative database for the company. The people behind digifai are experts in automation and software technology who can initiate and implement digitization projects – from the sensor to the last bit. This helps digifai customers to implement IoT projects easily and without any complicated implementation steps.

Control uses existing structures

The control solution from digifai is based on networking thanks IoT. Data sources are accessed over the existing network and the Internet. One advantage is the WEB-based technology of the software. No software installations are required to use the IoT platform and it can be used from a wide range of devices with web connectivity, such as desktops, tablets or smartphones. This minimizes barriers to entry and makes it possible to operate the system across different versions of the devices-operating systems. Users of the IoT platform control log into the system via protected and secure access. Users can manage authorizations and notifications yourself. Thanks dashboards and favorites function, users can always find the information they need. Just like the iceberg principle, the user can navigate detailed information from the top to the detail ( up to the individual sensor value). The IoT platform is provided by digifai as a Software as a Service Solution (SAAS). This enables a scalable rollout for digitalization projects without the risk of bad investments in expensive software packages.

Using data to generate profit

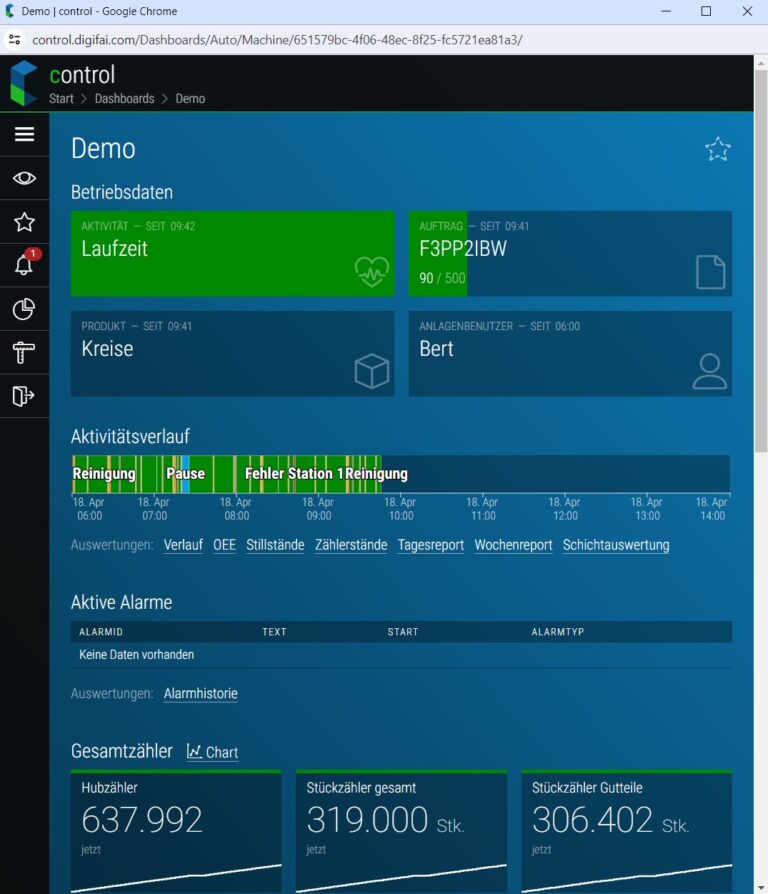

Existing analysis tools, tools and functions in the IoT platform control generate added value from the collected data and detect anomalies at an early stage. From the recorded machine and process data, control generates key performance indicators (KPIs). These values generated from the raw measurement data can also be included in the automated monitoring. If performance falls or quality drops, notifications or workflows can be triggered via the IoT control platform. Analysis tools make it possible to make correct measurements in recorded data series. Reporting is also digitized and automated with control. Daily, shift and weekly reports can be created at the simple and automated of one click. Summarized data is displayed in dashboards or Shopfloor views. Predictive analyses provide support for maintenance and energy management. The functions in control give the user a digital knowledge advantage and processes can be optimized with specific and objective data. Control enables end-to-end information flows, makes information more available, minimizes downtime and delivers measurable results for your processes.

Advanced visualization for maximum transparency and faster access to information.

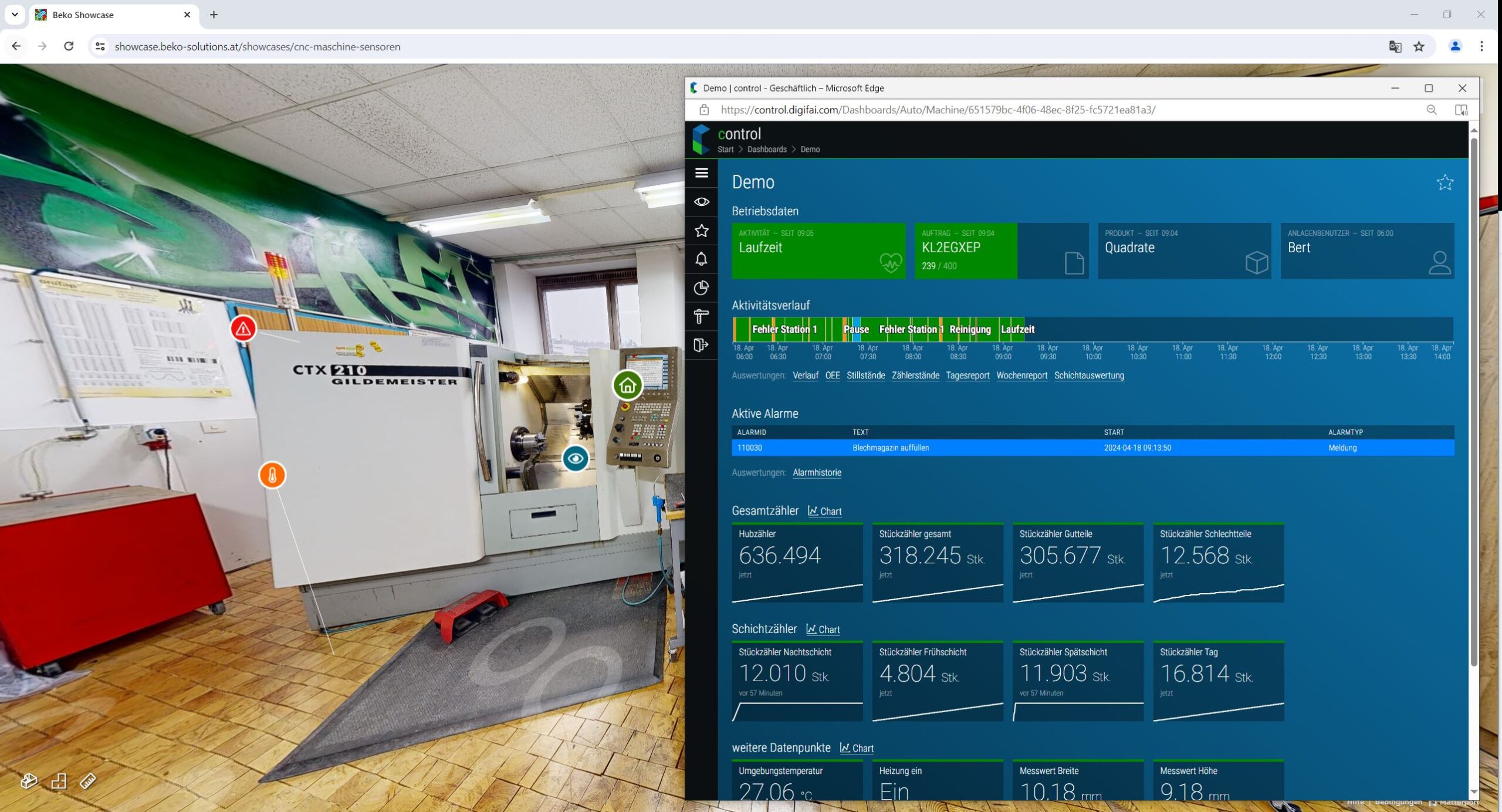

BEKO’s visualization not only provides a dashboard, but also creates a virtual environment that creates a realistic model of the real production facility without resorting to CAD models. A special scanning process creates a 3D model of the production plant in which you can move around easily. All relevant information is then integrated into this model. It can be accessed from anywhere via a web browser. This makes it easier to navigate to the different machines and parameters so for example alarms or sensors can be easily identified. BEKO’s visualization is the digital map of the production area. In combination with digifai control, a 360° view of the process environment is created. BEKO is one of Austria’s leading IT & technology service providers – the mission: innovative technologies, creative solutions and exciting jobs. Since over 50 years BEKO works with different companies, from global corporations to start-ups. BEKO offers a wide range of solutions – from tailor-made software solutions, digital consulting and project management to innovative 3D visualization. Customized showcases are created here and the possibility to edit them easily, quickly and efficiently is offered.

Figure 1: The control dashboard has a clear and responsive design, but still contains all the data for a quick, detailed insight.

Showcase online

The showcase is available online at the following link: https://showcase.beko-solutions.at/showcases/cnc-maschine-sensoren

// Product

More information on the IoT platform control

English

English Deutsch

Deutsch