// Software and solutions for the industry

Hello, we are digifai. We develop software and solutions that make the design and operation of machines safer and more efficient.

// More Quality & Efficiency – Less Risk

There is enormous potential in the digitalisation of processes. Our solutions make use of this. They help to develop and operate machines more efficiently, safely and comfortably – across all industries. The result: quality and efficiency increase while risks decrease.

// Product

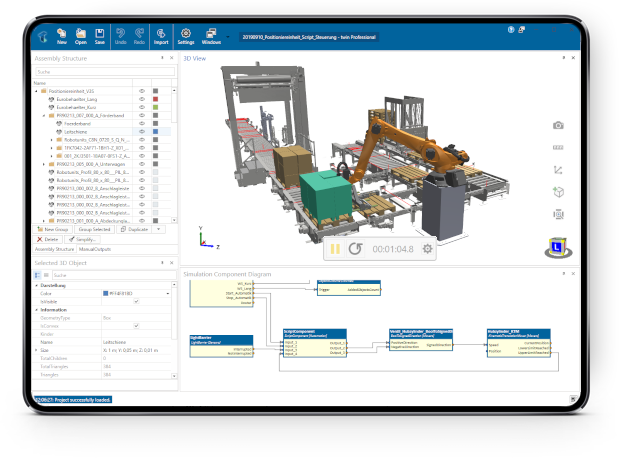

twin

The leading all-round simulation software for machines and robots. Efficient, safe and cost-saving from idea to operation with twin.

- Feasibility studies before starting automation projects

- Virtual commissioning in 3D on the digital twin

- Intuitive 3D HMI for machines in operation

// Product

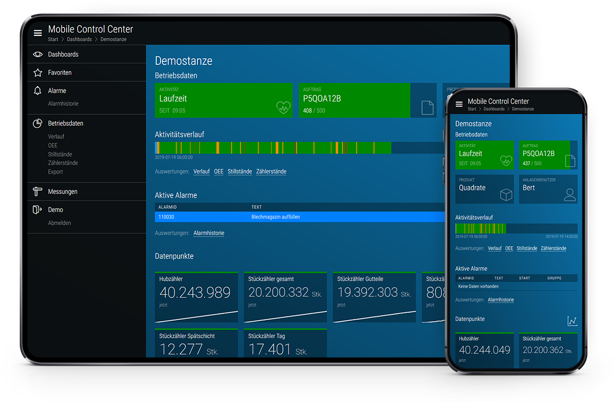

control

control connects, visualizes, notifies, analyzes and orchestrates process data independently from any location. You already have the source data – control shows you the relevant correlations.

- Industrial IoT Platform

- Acquisition, display and evaluation of machine key figures

- Clear, intuitive and ready to use

// Product

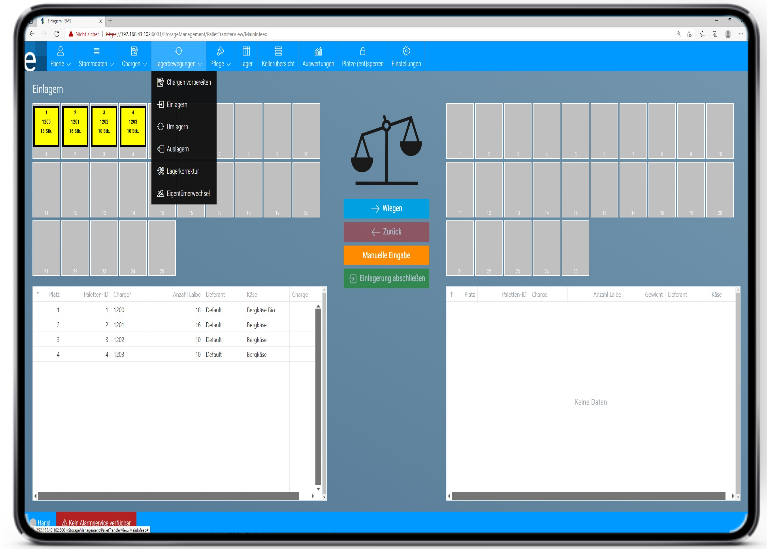

storage

storage is the market leader in cheese cellar logistics. The cheese ripening process is digitally recorded, clearly displayed and seamlessly documented. In addition, the complete care management in the ripening cellar is organized with storage.

- Optimal management of the cheese maturing process

- Simple and intuitive monitoring of warehouse activities

- Clear, digitized and traceability of all data at any time

- Location-independent monitoring through connection with IIoT platform

// References

Our Customers’ Opinion

twin enables us to create digital twins of our production machines. digifai’s many years of experience as an integration partner is visible in the small but important details of their solutions.

control is used in our quality management. The digital recording of process data improves data quality and eliminates the previously cumbersome and inaccurate manual recording.

The simulation software twin delivers what digifai promises. We are thrilled.

The software fulfils all our wishes – we can master even the most demanding requirements with twin. Such fast and competent support is unique. twin is constantly evolving and always focusses on customer needs. Keep up the good work!

We are an Austrian SME, develop turnkey special machines and have been looking for a suitable software for the virtual commissioning of our machines for a long time. With the software twin from digifai, we now secure the complete development process of our machines at an early stage and save valuable time during commissioning! With twin, we have definitely backed the right horse in this area!

Through the storage management software, we achieve a very high level of automation of the cheese ripening process. Storage organizes, plans and orchestrates the complete cheese ripening process from storage, through cheese care, to removal from storage. This ensures that storage is able to provide us with complete information about cheese care and our cheese stock at all times.

Digifai’s storage management software enables continuous, end-to-end monitoring and control of storage levels in the ripening cellar. Automation in the cheese warehouse means that all processes are monitored end-to-end and data is collected, providing interesting insights and safer planning for the future. With complete recording and documentation by storage, fast handling and processing of certification audits is guaranteed.

We chose storage to optimize our cheese cellar logistics. The software is easy to use and enables us to record the cheese ripening process digitally and across all locations. With storage we can create customized reports and have an overview of our cheese batches at any time. We are very satisfied with the solution and are happy to recommend it to others.

storage supports me in managing the ripening process of our high quality produced mountain cheeses in the Bregenzerwald cheese cellar. With the help of automatic documentation, the storage process is traceable at all times and rigorously minimizes administrative effort .

twin offers us as a medium-sized special machine manufacturer the possibility to minimize risks in the concept phase, to secure the design at an early stage and with the virtual commissioning a shorter time-to-market for our customers.

The possibility of simulating designs physically correctly, checking them for feasibility with various use cases and putting them into operation virtually opens up a completely new market access for us as a service provider in partnership with digifai.

By simulating the entire machine at an early stage, we can significantly reduce risk and save costs. The entire control software including HMI and control system is ready and tested before the machine is built.

During the project, the requirements regarding temperature display and alarm forwarding became more and more demanding. With digifai control we found the perfect solution to realize this project.

To conduct our research, we need a secure environment in which we can test AI algorithms for machines as realistically as possible. twin is perfectly suited for this purpose.

twin enables us to create digital twins of our production machines. digifai’s many years of experience as an integration partner is visible in the small but important details of their solutions.

control is used in our quality management. The digital recording of process data improves data quality and eliminates the previously cumbersome and inaccurate manual recording.

The simulation software twin delivers what digifai promises. We are thrilled.

The software fulfils all our wishes – we can master even the most demanding requirements with twin. Such fast and competent support is unique. twin is constantly evolving and always focusses on customer needs. Keep up the good work!

// Our Team Guides You Through Our World

Our Webinars

- Virtual commissioning with twin

- Digging up data treasures with control

// Our Team Guides You Through Our World

Our Webinars

- Monitoring

- Remote Solutions

- Big Data

- 3D user interfaces

- Human Machine Interface

// Contact

Curious?

Do you have a concrete project in mind or would you like advice on whether you can benefit from digifai? I look forward to your message.

Michael Eberle

Chief Technology Officer

+43 5572 55580 803

michael.eberle@digifai.com

// Our Products

The World of digifai at a Glance

Which project do you need a solution for? Here you can find our portfolio, our software. Our contribution to your digitalization.

twin

twin creates a digital twin. This allows you to test the controls of your system before the machine is set up.

control

control connects, visualizes, notifies, analyzes and orchestrates process data independently from any location.

storage

storage is the market leader in cheese cellar logistics. The cheese ripening process is digitally recorded, clearly displayed and seamlessly documented.

// Our Partners

Partners of digifai

Together with our partners, we are driving digitalization forward on a sustained basis. Would you also like to become part of the team? Contact us at info@digifai.com

English

English Deutsch

Deutsch